Product Center

Product Classification

Contact Information

Address: Room 1502, Building 2, No. 39, Shangyi Road, Minhang District, Shanghai

Phone:021-64130068

Mobile:18221910198(same as WeChat)

Fax:021-64135086

Email:asli@shinelong.com

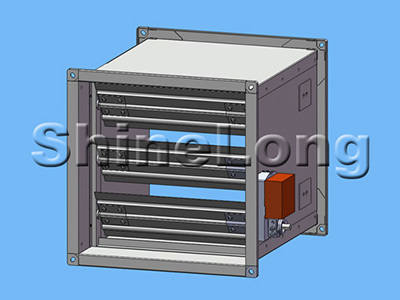

FHF WSDq-K fire damper

- Commodity name: FHF WSDq-K fire damper

- Product Description

- Technical parameters

-

Performance :

1、 Normally open, it cuts off power or gas source in case of fire, the valve automatically closes, and outputs a closing electrical signal.

2、 The valve can be manually closed or closed by ℃ temperature sensor.

3、 After the valve action, the temperature sensor is not damaged, and it automatically resets after power and gas are restored.

4、 It can be remotely closed electrically.

Structure :

Main components: valve body, blade, shaft, bushing, temperature sensor, actuator, stainless steel spring plate, torsion spring, etc.

W direction plus intermediate frame, blade separation

Maximum valve size: 1250*800

W×H matches the duct size, and the flange size is the same as the flange of the metal rectangular duct in national standard GB50234-2002.

Conditions of Use :

Static Pressure: Below 1500Pa

Maximum air flow velocity: 15m/s

Ambient operating temperature: -10℃~50℃

Ambient operating humidity: Relative humidity Below 85%

-

Main Technical Parameters :

Temperature sensor activation temperature: 70℃

Fire resistance rating of valve: 1.5h

Air leakage (pressure difference 300Pa) ≤500m3/m2.h

Control voltage: DC24V

Operating current: ≤0.7A

Microswitch contact capacity: AC220V 3A

Rotation direction: Closes clockwise when activated

Action time: Instantaneous

Pneumatic circuit diagram :

Wiring diagram :

Note: T is the normally open contact of the relay

Precautions

1. Users should not paint the outside of the actuator during use, and should not add oil to the electrical components, as this may cause malfunctions.

2. Fire dampers are related to life safety and must be installed and debugged by professionals. Regular checks of opening, closing, electrical signal operation, and temperature sensors should be performed every six months during normal use.

Keywords:

Product Inquiry

Please leave your email address, and our professionals will contact you as soon as possible!