Product Center

Product Classification

Contact Information

Address: Room 1502, Building 2, No. 39, Shangyi Road, Minhang District, Shanghai

Phone:021-64130068

Mobile:18221910198(same as WeChat)

Fax:021-64135086

Email:asli@shinelong.com

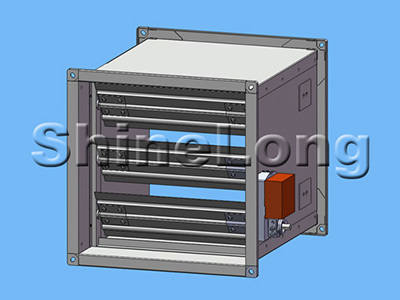

Fire damper series installation and maintenance matters

- Commodity name: Fire damper series installation and maintenance matters

- Product Description

- Technical parameters

-

Product Installation Precautions:

1. Before installing the valve, check if the valve's exterior and operating mechanism are intact, if the operation is flexible, and confirm that all directions are normal before installation.

2. The temperature sensor on the valve should be on the windward side. 3. The valve body is not allowed to deform during installation, and the valve should open and close flexibly after installation.

4. The fire damper should have a separate bracket to prevent the duct from affecting the valve function due to high-temperature deformation.

5. There should be a clear space of no less than 250 mm on the side of the valve's operating mechanism for maintenance.

6. When the valve is installed inside the ceiling (or wall), an inspection hole should be opened below the actuator of the valve, with dimensions no less than 450 × 450.

Product Maintenance and Management:

1. Do not transport outdoors in rainy days, do not store outdoors, should be stored in a rainproof, waterproof, ventilated, clean, and well-lit warehouse, and placed neatly to prevent damage and deformation.

2. Products should be inspected and maintained regularly according to the requirements of fire safety management to ensure normal operation. Generally, inspection should not exceed 6 months, and records should be kept.

3. Main contents of regular inspection:

Connect the power supply, check if the electromagnet is working, if the valve is working quickly, and check if the valve blades are flexible and reliable.

Connect the power supply, check if the motor is working, and if the valve is flexible and resets.

Check if the microswitch is correctly connected and if the electrical signal feedback is correct.

If any damage to the components is found during the inspection, they should be replaced immediately. The valve can only be reset after confirming that there is no fault.

Check the electrical wiring of the remote control device, control steel wire rope, etc., for any damage or deformation. The valve can only be reset after confirming that there is no fault.

Check whether the temperature sensor performance is reliable. If the temperature sensing element is found to be broken or detached, it should be replaced immediately to ensure safety. If the temperature sensing element is found to be detached or needs to be replaced regularly according to fire safety management requirements, the following procedures can be followed:

a). Open the pressure cover on the actuator, unscrew the temperature sensor clamping nut, and remove the temperature sensor.

b). Loosen the clamping spring and remove the fuse tube.

c). Install the new fuse tube and tighten the spring nut.

d). Install the fuse in its original place, then tighten the nut, and install the actuator pressure cover.

The following figure shows two different methods for replacing the temperature sensing element of the temperature sensor.

Fire Damper Series

Smoke Exhaust Valve Series

Keywords:

Product Inquiry

Please leave your email address, and our professionals will contact you as soon as possible!